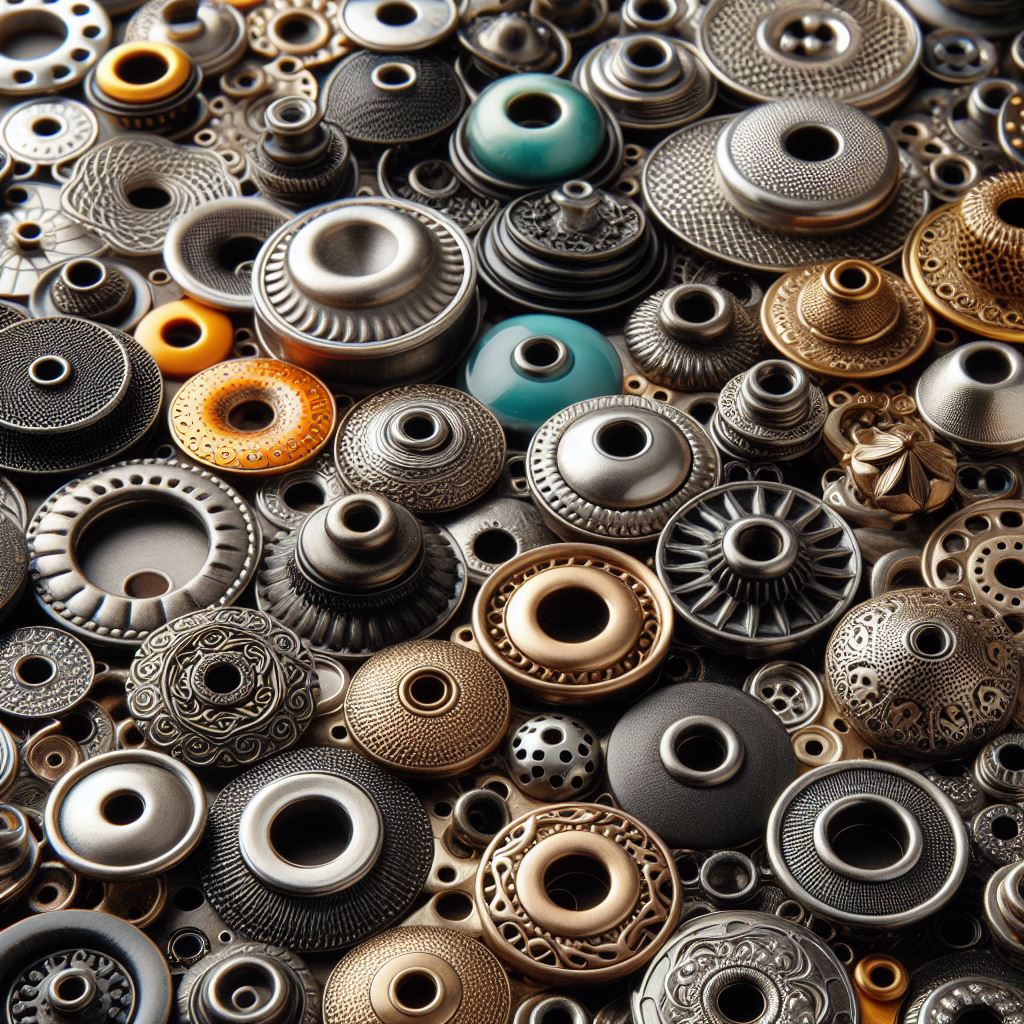

In the domain of garment assembly and textile embellishment, eyelets stand as pivotal components, serving as both functional reinforcements and decorative accents. These small yet essential fasteners are comprised of various elements that contribute to their functionality and aesthetic versatility. Gaining insights into the diverse parts and types of eyelets can provide valuable guidance for designers and manufacturers seeking to integrate them into their creations. Let’s unravel the structure and diversity of eyelets:

Structure of Eyelets:

- Ring: The ring, or eye, of an eyelet, is the central component that forms the opening through which lace, cord, or another fastening mechanism can pass. It can come in various shapes, including round, oval, or rectangular, depending on the desired aesthetic and functional requirements.

- Shaft: The shaft, also known as the barrel or body, is the cylindrical portion of the eyelet that extends through the fabric or material. It provides structural support and stability, ensuring that the eyelet remains securely in place and withstands tension and stress without deforming or pulling through the fabric.

- Flange: The flange is the flat, disc-shaped portion of the eyelet that sits flush against the surface of the fabric. It serves to distribute pressure evenly and prevent the eyelet from sinking into the fabric when compressed or crimped. The flange also adds stability and reinforcement to the attachment point, enhancing the durability of the eyelet.

Types of Eyelets:

- Grommet Eyelets: Grommet eyelets are heavy-duty eyelets typically made of metal or reinforced plastic. They feature a wide flange and a robust construction, making them ideal for applications where strength and durability are paramount, such as in industrial settings, tarpaulins, and outdoor gear.

- Brass Eyelets: Brass eyelets are crafted from brass, a corrosion-resistant alloy of copper and zinc. They offer a classic and elegant appearance, with a warm, golden hue that adds sophistication to garments, leather goods, and accessories. Brass eyelets are popular in applications where a refined and timeless aesthetic is desired.

- Nickel Eyelets: Nickel eyelets are made from nickel-plated brass or steel, offering a sleek and contemporary look. They are highly resistant to corrosion and tarnishing, making them suitable for outdoor and marine applications where exposure to moisture and harsh environmental conditions is common.

- Plastic Eyelets: Plastic eyelets are lightweight and versatile, available in a wide range of colors, shapes, and sizes. They are often used in applications where metal eyelets may be unsuitable due to weight or conductivity concerns, such as in children’s clothing, swimwear, and lightweight fabrics.

- Reinforced Eyelets: Reinforced eyelets feature additional reinforcement, such as metal or plastic washers, inserted between the flange and the fabric to provide extra stability and support. They are commonly used in high-stress areas or applications where the fabric may be prone to tearing or fraying, such as in canvas, denim, and workwear.

- Self-Piercing Eyelets: Self-piercing eyelets, also known as self-setting or punch eyelets, feature a sharp, pointed shaft that can penetrate through the fabric without the need for pre-punching holes. They offer a quick and efficient fastening solution, reducing production time and labor costs in applications such as banners, signage, and promotional materials.

In summary, eyelets are indispensable components that offer both functionality and decorative appeal in garment construction and textile embellishment. By understanding the structure and diversity of eyelets available, designers and manufacturers can select the ideal option to suit their specific needs and creative vision. Whether opting for grommet, brass, nickel, plastic, reinforced, or self-piercing eyelets, these versatile fasteners offer endless possibilities for customization and innovation in the world of fashion and textiles.